Mastering DTF Printing: A Comprehensive Guide to Direct-to-Film Techniques

Mastering DTF Printing: A Comprehensive Guide to Direct-to-Film Techniques

Blog Article

The Future of Style: Exploring DTF Printing Technology in the Fabric Market

Recently, the textile market has witnessed a significant shift in the direction of cutting-edge modern technologies that are reshaping the landscape of fashion manufacturing. Amongst these advancements, Straight to Movie (DTF) printing innovation has emerged as an appealing competitor, using unique capabilities and chances for developers and producers alike. This advanced printing method has actually stimulated passion due to its potential to reinvent standard fabric printing procedures. As we look into the effects and possibilities of DTF technology in the realm of style, it comes to be obvious that its integration can redefine market criteria and lead the method for a new age of imaginative expression and efficiency.

Advancement of Textile Printing

Throughout history, the advancement of fabric printing has actually been a testament to the cutting-edge developments in this complex art kind. From the ancient civilizations utilizing strategies like block printing to the digital transformation these days, fabric printing has constantly pushed boundaries. The beginnings of textile printing can be mapped back to China around 220 AD, with using wooden blocks to print on silk materials. As the craft spread to other parts of the world, new methods such as screen printing and roller printing emerged during the Industrial Change, reinventing the fabric industry - DTF Printing.

The intro of digital textile printing in the late 20th century noted a considerable change in the direction of more sustainable and functional printing approaches. The evolution of textile printing showcases a rich history of imagination, resourcefulness, and technical development in the world of fashion and design.

Benefits of DTF Technology

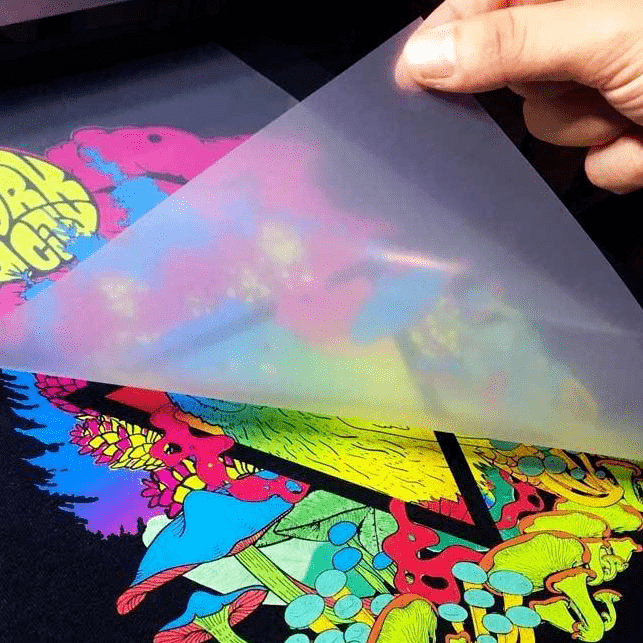

With the advancement of fabric printing strategies from ancient techniques like block printing to modern-day innovations such as digital printing, the intro of Direct-to-Fabric (DTF) innovation has actually considerably boosted the effectiveness and sustainability of textile printing procedures. Among the key benefits of DTF technology is its ability to straight print designs onto textile without the requirement for transfer documents, which reduces waste and streamlines the production procedure. Additionally, DTF printing permits higher color vibrancy and detail precision compared to typical methods, enabling fabric suppliers to create elaborate and top quality layouts with ease.

In addition, DTF modern technology is recognized for its flexibility, as it can be made use of on various sorts of fabrics, consisting of natural fibers like silk, woollen, and cotton, in addition to artificial materials such as polyester and nylon (DTF Printing). This adaptability opens up a wide variety of possibilities for manufacturers and designers to try out different textures and materials, resulting in more cutting-edge and special items in the apparel industry. On the whole, the application of DTF technology stands for a considerable improvement in textile printing, offering various advantages that add to the future sustainability and creativity of the industry

Sustainability in Style Manufacturing

Emphasizing green practices is extremely important in contemporary style manufacturing, lining up with the expanding consumer demand for sustainable products. Recently, the style industry has actually encountered raising analysis as a result of its significant ecological impact, consisting of too much water use, chemical air pollution, and fabric waste. As a response, lots of fashion brand names are now including sustainable techniques right into their manufacturing processes to minimize injury to the atmosphere.

Sustainability in vogue manufacturing includes various aspects, such as using natural and my company recycled products, reducing power intake, executing ethical labor methods, and promoting transparency throughout the supply chain. Additionally, advancements in modern technology, like DTF printing, deal possibilities to even more improve sustainability in textile production. This technology enables precise printing on textiles, lowering ink wastage and water usage contrasted to typical printing methods.

Layout Flexibility and Customization

In addition, DTF printing assists in customization on a range previously unattainable, allowing for customized clothes and unique items customized to private choices. In general, DTF printing modern technology revolutionizes the design landscape in the textile sector, providing endless opportunities for creative expression and tailored fashion.

Influence On Supply Chain & Market Trends

DTF printing modern technology in the textile industry is reshaping supply chain dynamics and affecting market fads through its efficiency and customization capabilities. By allowing on-demand printing and removing the demand for large inventories, DTF modern technology simplifies the supply chain process. Manufacturers can produce products as required, reducing waste and storage space expenses. This just-in-time manufacturing design likewise permits quicker feedback to market demands and trends, bring about a much more agile and responsive supply chain.

Moreover, click for source the customization capacity of DTF printing technology is reinventing the market trends in the fabric industry. Customers increasingly seek distinct and personalized products, and DTF allows brand names to offer custom layouts cost-effectively. This personalization capability not just improves consumer complete satisfaction however also opens up brand-new possibilities for services to deal with niche markets and separate themselves from rivals. Consequently, DTF modern technology is driving a shift towards more customer-centric and ingenious strategies within the fabric industry, forming the future of fashion.

Conclusion

In conclusion, DTF printing technology is transforming the fabric industry by providing many benefits such as layout flexibility, sustainability, and personalization. This ingenious modern technology is improving the future of fashion manufacturing, affecting supply chains, and driving market trends towards more eco-friendly and effective practices. As the industry proceeds to progress, DTF printing will certainly play try here a critical duty fit the method fabrics are produced and consumed in the years ahead.

From the old human beings using strategies like block printing to the electronic change of today, textile printing has actually continuously pressed borders. As the craft spread to various other parts of the world, new approaches such as display printing and roller printing emerged during the Industrial Transformation, changing the fabric industry.

The intro of electronic fabric printing in the late 20th century marked a significant shift towards even more lasting and versatile printing approaches.With the development of textile printing strategies from ancient methods like block printing to contemporary innovations such as electronic printing, the intro of Direct-to-Fabric (DTF) innovation has significantly enhanced the effectiveness and sustainability of fabric printing procedures (DTF Printing).In action to the important shift towards sustainability in fashion production, the fostering of cutting-edge innovations like DTF printing not only addresses environmental worries but additionally opens up avenues for unequaled design flexibility and customization in the fabric industry

Report this page